Aluminum Casement Windows

Aluminum casement windows are a versatile and stylish choice for modern architecture. Hinged on the side and able to open outward or inward, they provide excellent ventilation, clear views, and a clean, timeless look suitable for both classic and contemporary spaces.

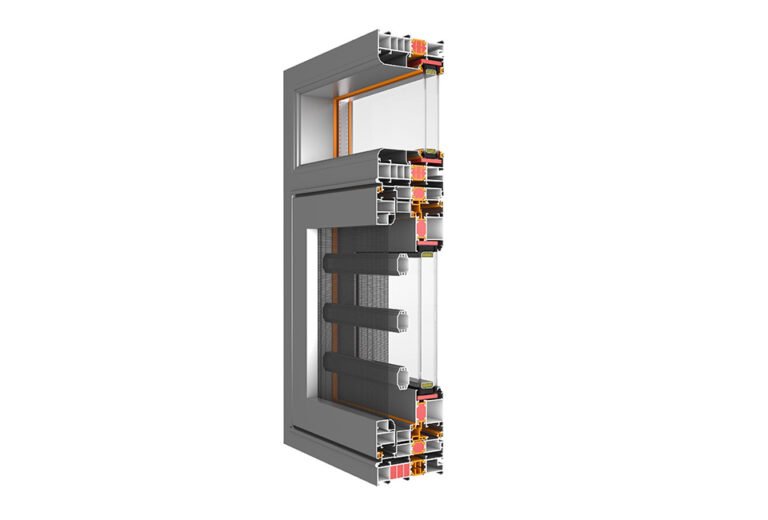

At Delanshini, each aluminum casement window is crafted with precision-engineered frames, premium hardware, and advanced sealing systems to ensure smooth operation, durability, and energy efficiency. Available in customizable sizes, colors, and glazing options, our windows bring the perfect combination of performance, comfort, and aesthetics to any residential or commercial project.

Advantages of Aluminum Casement Windows

Excellent Ventilation

Casement windows open fully outward, allowing maximum airflow into the room. This design captures side breezes effectively, improving indoor air circulation and comfort.

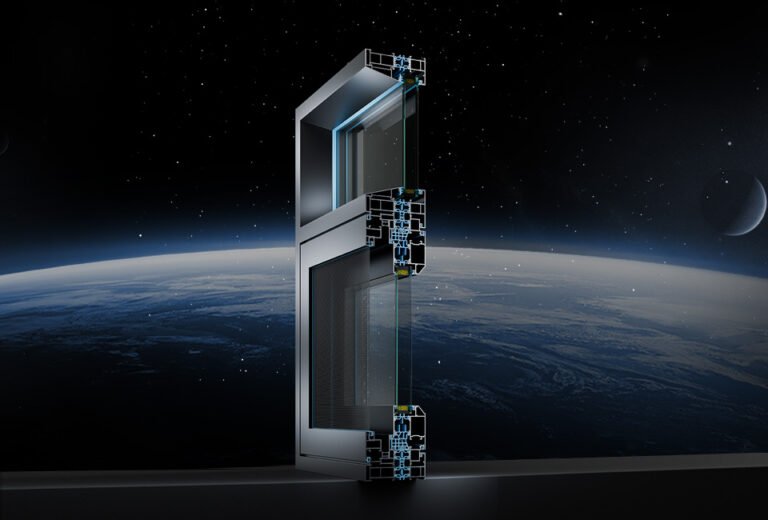

Energy Efficiency

When closed, the sash presses tightly against the frame, creating a superior seal that minimizes air leakage. Combined with thermal break profiles and insulated glass, this helps reduce heat transfer and energy costs.

Advantages of Aluminum Casement Windows

Durability and Low Maintenance

Aluminum is naturally resistant to rust, corrosion, and warping, making casement windows long-lasting even in harsh weather conditions. They require minimal upkeep—just occasional cleaning.

Modern Aesthetic Appeal

The slim aluminum frame offers a sleek and contemporary look that complements both residential and commercial designs. It allows for larger glass areas, maximizing natural light and outdoor views.

Smooth and Secure Operation

Equipped with high-quality hinges and multi-point locking systems, aluminum casement windows operate smoothly and provide enhanced security against forced entry.

Design Flexibility

Available in various colors, finishes, and opening configurations, aluminum casement windows can be customized to match architectural styles and individual preferences.

Casement Window Types

Side-Hinged Casement Window

Side-Hinged Casement Window is the most common type of casement windows, hinged on the left or right side. They can be operated with a crank or push mechanism and are versatile for most room types.

Top-Hinged Casement Window

Top-Hinged Casement Window is hinged at the top and open outward from the bottom. They are especially useful for ventilation even during rain, as the sash acts as a protective awning.

Bottom-Hinged Casement Window

Bottom-Hinged Casement Window is hinged at the bottom and open inward from the top. They are commonly used in basements or areas where outward opening is not feasible.

Casement Window Sizes

Standard Casement Window Sizes

There are no universal standard sizes for casement windows, as homes differ greatly in design, style, and age. However, manufacturers of pre-made windows typically offer a selection of commonly used sizes. While these standard sizes may not perfectly match every opening, they are generally close enough to allow installation with minor adjustments to the surrounding masonry or drywall.

Custom Casement Window Sizes

Delanshini also provides custom window sizes to suit specific design or installation requirements. Our engineering team can adjust frame depth, sash size, and opening direction to ensure a perfect fit and seamless integration with your building façade.

Custom Solutions

We offer a wide range of design options to suit any project:

Production Process of Aluminum Casement Window

Every Delanshini aluminum windows and doors are crafted through a rigorous, precision-controlled production process to ensure superior quality and long-lasting performance.

Why Delanshini?

Decades of engineering experience

High-quality raw materials and German-level craftsmanship

Reliable supply for large-scale and custom projects

Technical support and OEM/ODM service

Ready to elevate your next project?

Get in touch with our experts to discuss your design goals and find the aluminum windows solution tailored to your specifications.