Aluminum Sliding Windows

Aluminum sliding windows are a modern and practical solution for both residential and commercial buildings. Designed with sleek frames and smooth operation, they provide excellent ventilation and natural light while saving space. With their elegant appearance, durability, and easy maintenance, aluminum sliding windows have become one of the most popular window styles for contemporary architecture.

At Delanshini, we manufacture high-quality aluminum sliding windows that combine precision engineering with stylish design. Our products are available in a variety of configurations, finishes, and glazing options to meet different project requirements.

Advantages of Aluminum Sliding Windows

Space-Saving Design

Unlike traditional casement windows that open outward or inward, sliding windows glide horizontally along a track. This makes them ideal for areas with limited space, such as balconies, corridors, or compact rooms.

Smooth and Silent Operation

Equipped with high-performance rollers and tracks, our aluminum sliding windows open and close effortlessly. The precision-engineered mechanism ensures long-term smoothness and quiet movement.

Advantages of Aluminum Sliding Windows

Durability and Strength

Aluminum is naturally resistant to corrosion, rust, and weather damage. Combined with high-grade surface treatments such as anodizing or powder coating, our sliding windows can withstand harsh outdoor conditions for years with minimal maintenance.

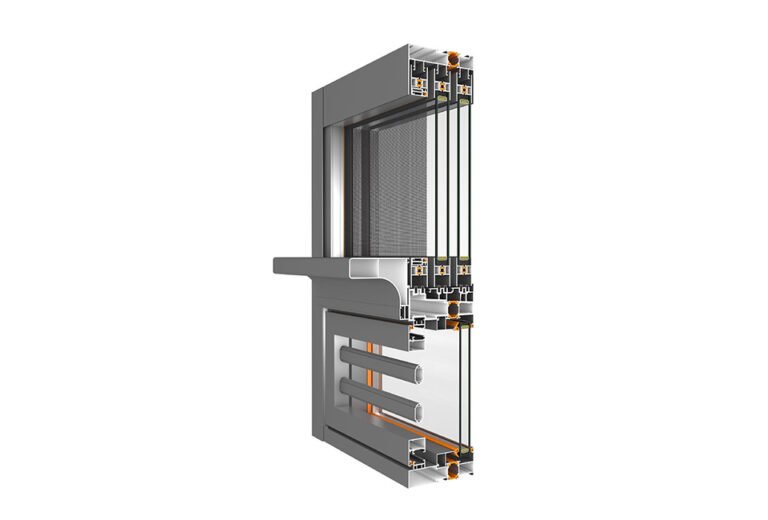

Energy Efficiency and Insulation

With double or triple glazing and optional thermal break profiles, aluminum sliding windows help improve energy efficiency and sound insulation, keeping indoor spaces comfortable year-round.

Modern Aesthetic Appeal

The slim aluminum frames offer a minimalist, contemporary look that complements any architectural style. Wide glass panels create an open view and enhance natural daylight.

Ease of Maintenance

Sliding windows have fewer moving parts and no hinges to maintain. Their simple design makes cleaning, lubrication, and upkeep effortless—ideal for busy modern lifestyles and large-scale installations.

Sliding Window Types

There are no universal industry-standard sizes for aluminum sliding windows because buildings vary in design and structure. However, common ready-made sizes include:

Two-Panel Sliding Window

A simple and functional design featuring one fixed panel and one sliding panel. It’s the most common choice for residential and office buildings.

Three-Panel Sliding Window

Offers a wider opening and flexible operation—two panels can slide behind the fixed one, allowing better ventilation and visibility.

Four-Panel Sliding Window

Ideal for large openings or panoramic views, this design includes two fixed and two sliding panels that move smoothly in both directions.

Corner Sliding Window

A stylish option for modern homes or commercial spaces, providing an uninterrupted corner view and maximum daylight.

Vertical Sliding (Sash) Window

A variation where the panels slide vertically instead of horizontally—perfect for traditional or limited-width spaces.

Sliding Window Sizes

There are no universal industry-standard sizes for aluminum sliding windows because buildings vary in design and structure. However, common ready-made sizes include:

2-Panel Sliding Window

Width 1200–1800 mm × Height 900–1500 mm

3-Panel Sliding Window

Width 1800–2400 mm × Height 1000–1800 mm

4-Panel Sliding Window

Width 2400–3600 mm × Height 1000–2100 mm

These can be adjusted to fit most openings with minor wall or frame modifications. For special projects, we also offer fully customized dimensions.

Custom Solutions

At Delanshini, we understand that every project is unique. Our team provides custom aluminum sliding window solutions tailored to your architectural vision. From frame colors and glass types to locking systems and thermal performance options, every detail can be personalized.

We work closely with designers, builders, and homeowners to deliver high-performance windows that match both functional requirements and aesthetic goals.

Production Process of Aluminum Sliding Windows

Every Delanshini aluminum windows and doors are crafted through a rigorous, precision-controlled production process to ensure superior quality and long-lasting performance.

Why Delanshini?

Decades of engineering experience

High-quality raw materials and German-level craftsmanship

Reliable supply for large-scale and custom projects

Technical support and OEM/ODM service

Ready to elevate your next project?

Get in touch with our experts to discuss your design goals and find the aluminum sliding windows solution tailored to your specifications.